Can Motek Jewelry Save Your Last-Minute Jewelry Dreams? The "Rush Job" Unpacked

Imagine this: your wedding is in three days, and you suddenly realize you absolutely need a pair of stunning hoop earrings, but not just any hoops – you envision them gleaming with the brilliance of lab-grown diamonds, or a specific shade of ruby - a modern twist on a classic. Or perhaps an unexpected anniversary has snuck up, and a unique, custom-designed pendant is the only gift that will do. These aren't just purchases; they're urgent quests for perfection. At Motek Jewelry, we understand that life happens, and sometimes, your jewelry needs a superhero-level expedited service. But what really goes into making these "rush jobs" a reality? It's far more intricate than simply grabbing an item off the shelf. Let's pull back the curtain and reveal the meticulous dance of precision, speed, and collaboration that ensures your urgent jewelry dreams come true.

Rush jewelry jobs are all about the relationships - yours and your loved ones, as well as Motek Jewelry and our team of expert craftsmen and trusted vendors.

Phase 1: The Urgent Spark: Decoding Your "Rush" Jewelry Request

Question/Problem Addressed: What constitutes a "rush" jewelry request, and what are the initial considerations for a jeweler when faced with a tight deadline for both custom and stock pieces?

When time is of the essence, every second counts. A "rush" job in the jewelry world isn't just about moving fast; it's about flawlessly executing a complex series of steps under immense pressure. It begins with a deep dive into your specific needs, even for seemingly straightforward requests like changing the stone in a stock item.

For custom designs, a "rush" amplifies every stage of creation. Think of the bride who wants a bespoke pair of earrings, unique and perfectly matched to her gown, but her wedding is days away. This isn't just about drawing a sketch; it's about translating that vision into a precise CAD (Computer-Aided Design) model, ensuring every curve and angle is perfect for a rapid 3D print and casting. The challenge lies in compressing weeks of iterative design and approval into a matter of hours, often requiring real-time collaboration and decisive decision-making from the client. Bentzion Yehoshua, founder and lead designer at Motek Jewelry, emphasizes, "In a rush custom job, the initial design conversation is paramount. We need to capture the client's essence and translate it into a feasible, fast-trackable design without compromising our 'Quality First' motto." This involves presenting streamlined options, relying on our extensive experience to anticipate potential issues, and having a clear, concise approval process.

Stock pieces, while seemingly simpler, also present unique "rush" challenges, especially when modifications are involved. Take our example: a client needs hoop earrings, off-the-shelf, but wants them in lab-grown diamonds in the highest premium quality instead of naturals at standard above average quality. This isn't just a simple swap. It requires:

-

Immediate Inventory Check: Is the specific hoop style available in the desired metal (e.g., 14K yellow gold) and size?

-

Lab-Grown Diamond Availability: Are the exact size, color, and clarity of lab-grown diamonds in stock from a trusted vendor? This is crucial, as lab-grown diamonds, while increasingly popular, still have specific inventory cycles.

-

Quality Labor Availability & Project Timeline: Are our preferred craftsmen available for the job? What does their work schedule look like - are they able to shift timelines and pause other active jobs to accommodate our rush job?

-

Feasibility Assessment: Can the existing setting accommodate the new stones, or does it require modification? What about the karat of the gold? Ensuring a seamless fit without compromising the structural integrity or aesthetic appeal of the piece is paramount.

The urgency of the situation demands immediate action and a highly organized approach. From the moment you contact Motek Jewelry with a "rush" request, our team swings into action, assessing the feasibility, identifying potential roadblocks, and mapping out a precise timeline. It’s a rapid-fire consultation where experience and an extensive network become invaluable assets.

Phase 2: The Treasure Hunt: Sourcing Stones and Metal During Peak Season

Question/Problem Addressed: How does a jeweler quickly source specific karats, colors, and stone sizes for rush jobs, especially during challenging periods like holiday season when many vendors are overwhelmed with the business of peak season or are out of the country on vacation seasons?

Imagine a summer vacation season. Many businesses operate on reduced staff or are completely closed. Now, picture needing a very specific type of lab-grown diamond - say, perfectly matched pairs of 0.75, 1, 1.15 and 1.75 carat elongated radiant cuts, Fancy Intense Yellow color, VVS clarity - for an urgent pair of dangle earrings set on yellow gold. This isn't a task for the faint of heart; it's a high-stakes treasure hunt.

The first hurdle is finding a vendor who is not only open but also adequately stocked. This is where Motek Jewelry's long-standing relationships with a global network of trusted suppliers truly shines. Our team has cultivated connections over decades (often leaning on relationships with vendors generations old), allowing us to bypass common obstacles. Our network isn't just about quantity, it's about quality and reliability. We know which suppliers maintain robust inventories even during holiday slowdowns, and who can respond immediately to an urgent request.

The process goes something like this:

-

Immediate Outreach to Primary Vendors: We reach out to our top-tier gem and metal suppliers first. These are partners with whom we have established credit lines and a history of rapid transactions. We inquire about specific inventory – the precise karat (e.g., 14K or 18K gold), the desired metal color (yellow, white, rose, or platinum), and the exact stone specifications (carat weight, color, clarity, cut).

-

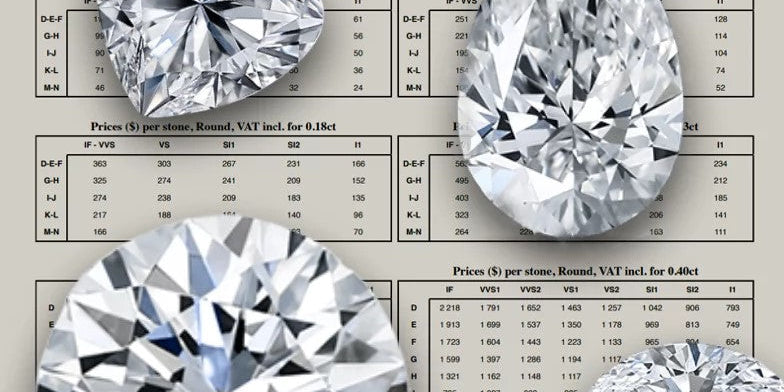

Verifying Stock and Quality: Even if a vendor is open, confirming they have the exact item in physical stock is critical. We can't rely on online inventories that might be updated infrequently. This often involves direct phone calls, immediate photo confirmations, or even video calls or office visits to visually inspect the items. We ensure stones all match in terms of size, color, clarity, and cut. For diamonds, we confirm the GIA or IGI certificate details, and ensuring the stones meet our rigorous quality standards is a non-negotiable step, even under pressure.

-

Expedited Shipping Logistics: Once the items are confirmed, the next challenge is getting them to the Motek Jewelry workshop, sometimes across continents, in record time. This sometimes involves arranging specialized couriers, often with direct-to-bench delivery, bypassing standard shipping channels. The costs associated with such expedited services are naturally higher, a factor we openly communicate with our clients.

-

Backup Vendor Activation: What if the primary vendor falls short? This is where a well-established "Plan B" (and sometimes C, D, and E) comes into play. We activate our network of secondary and tertiary suppliers, often specialized in specific types of stones or metals, to cast a wider net. This might mean leveraging relationships with smaller, boutique diamond houses or specialized metal refineries that can fulfill niche requests quickly.

-

Navigating International Time Zones and Holidays: Vacation and holiday seasons often mean different holidays across the globe. Our team is adept at navigating these complexities, understanding which regions are operating and which are not, allowing us to strategically source from areas that are active. This global awareness is a significant advantage in a time-sensitive situation.

This multi-faceted approach to sourcing is what allows Motek Jewelry to cut down lead times dramatically. It's a testament to years of relationship building and a deep understanding of the global jewelry supply chain, ensuring that even when the clock is ticking, the quality of your materials remains uncompromised.

Phase 3: The Art of Precision: The Setter's Race Against Time

Question/Problem Addressed: What meticulous steps does a diamond setter undertake to ensure secure and beautiful stone placement in a "rush" jewelry order, especially when dealing with new stone types like lab-grown diamonds in existing settings?

Once the perfect stones and metal arrive at the Motek Jewelry workshop, the clock continues to tick. The next critical stage is stone setting, a phase that demands extraordinary precision, even more so under "rush" conditions. This is where the artistry and expertise of a master setter truly shine.

For a client desiring a stock hoop modified with lab-grown diamonds, the setter faces several nuanced challenges:

-

Preparation of the Mounting: Even "off-the-shelf" settings often require preparation for new stones. Beyond the standard preparation that goes into mounting stones in a fresh setting, we sometimes use the original setting and set new stones inside. If the original natural diamonds are being replaced with lab-grown ones of slightly different dimensions (even minute differences can impact the fit), the existing seats (the tiny ledges in the metal that hold the stone) may need to be carefully adjusted. This involves using specialized burs and gravers to subtly re-shape or enlarge the opening, ensuring the lab-grown diamond sits perfectly flush and level. Too much, and the stone is loose; too little, and it won't seat properly. This is an art form in itself, requiring a steady hand and an experienced eye.

-

Securing the Stones – The Right Setting Technique: The choice of setting technique is vital for both aesthetics and durability. For hoop earrings, often involving pavé or channel settings for smaller stones, or prong settings for larger ones, the setter must work with extreme care.

-

Prong Setting: If the hoops feature individual prongs, each tiny claw of metal must be carefully pushed over the girdle (the widest part) of the lab-grown diamond. This isn't just about bending metal; it's about creating enough pressure to hold the stone securely without damaging it or distorting the setting. In a rush, this often means working with heightened focus, as re-doing a prong can add significant time.

-

Pavé/Bead Setting: For pavé-set diamonds, where multiple small stones are set closely together, tiny beads of metal are raised from the surface to hold each diamond. This requires a microscope and incredibly fine tools. The setter must ensure that each bead is uniform, secure, and contributes to the overall sparkle of the piece, not detracting from it.

-

Channel Setting: If the diamonds are to be set in a channel, the setter must ensure the groove is precisely cut to allow the diamonds to slide in snugly, then carefully "burnish" the metal walls over the edges of the stones to secure them. This is often done from the underside or side of the channel, requiring specialized tools and immense skill.

-

-

Preventing Damage to Stones: All diamonds, while incredibly hard and durable, can still chip or scratch if mishandled during setting. The setter must be acutely aware of the stone's angles and pressure points, especially during aggressive manipulations of the metal required when setting a stone. This is particularly true in a rush job, where the temptation might be to work faster, but a true artisan maintains their meticulous approach. One of Bentzion's favorite lessons from his benchwork mentors is that "the best advice for an aspiring master jeweler is to do it right the first time."

-

Maintaining Aesthetic Flow: Beyond security, the setter must ensure the diamonds are aligned perfectly, their facets catching the light uniformly. Any slight misalignment can detract from the overall brilliance and beauty of the piece. In a rush job, maintaining this aesthetic perfection while adhering to a strict timeline is a hallmark of an expert.

Bentzion personally oversees the critical aspect of quality control for rush orders, leveraging his years of experience to make fast precise decisions & small adjustments during final inspection to ensure that the job was done right. There's no room for error in a rush job. Every movement has to be deliberate, efficient, and perfectly executed to ensure the piece is not only finished on time but also meets our highest standards of craftsmanship. This stage is a testament to the blend of technical skill and artistic vision required to transform raw materials into a sparkling reality without compromising on quality.

Phase 4: The Final Polish: Gleam, Glamour, and Getting it to You Fast

Question/Problem Addressed: What are the intricate stages of polishing and finishing jewelry, especially for rush orders, to achieve a flawless appearance while ensuring timely delivery?

After the stones are meticulously set, the jewelry piece, whether a custom design or a modified stock item, often looks dull and bears the marks of the setting process. This is where the magic of polishing and finishing comes in, transforming raw metal into a gleaming masterpiece. In a "rush" scenario, this final stage is a high-speed ballet of abrasive compounds, specialized tools, and expert hands.

The polishing process at Motek Jewelry is typically broken down into several granular steps, each designed to progressively refine the metal's surface:

-

Initial Grinding and Filing (Pre-Polishing): This isn't strictly polishing but is crucial for it. Any visible tool marks, casting imperfections, or excess metal from the setting process must be carefully removed. This involves using various files and specialized rotary tools with coarse abrasives. For rush jobs, this step needs to be incredibly efficient, as any missed blemish here will be magnified later.

-

Sanding and Smoothing (Graduated Grit): The piece then undergoes a series of sanding steps, moving from coarser grits to progressively finer ones (e.g., from 400-grit to 2000-grit or even higher). This removes scratches left by the previous filing and creates a smooth, uniform surface. Each grit level requires thorough attention, as failing to remove the marks from a coarser grit will mean they remain visible after the final polish. For urgent pieces, this process is often done with high-speed rotary tools by highly experienced polishers who can sense when a surface is perfectly smooth. This step is especially important with custom designed pieces that were fabricated with 3d printing of a resin model in the project pipeline, as the 3d printed jewelry has the layer lines show on the metal surface. they need to be smoothed out evenly before the final buff and polish otherwise the metal surface will look and feel uneven.

-

Rough Polishing (Buffing / Cutting Down): This stage uses specialized polishing compounds (like Tripoli for yellow metals or Zam for white metals) applied to rotating cloth buffs. This step actively "cuts down" the metal surface at a microscopic level, removing the finer scratches left by sanding and starting to bring out a shine. This generates significant heat, so the polisher must constantly move the piece to avoid overheating and potentially damaging the stones or softening the metal.

-

Fine Polishing (Final Polish): The next step involves a finer compound (like Rouge, often red for gold, or green for platinum) and a softer buff. This stage refines the surface even further, creating the high-luster, mirror-like finish associated with fine jewelry. This requires an incredibly light touch and keen eye to ensure an even, brilliant sheen across all surfaces, including intricate details and hard-to-reach areas around stones.

-

Ultrasonic Cleaning: After polishing, the piece is typically placed in an ultrasonic cleaner with a specialized solution. This uses high-frequency sound waves to dislodge any residual polishing compounds, dirt, or debris from the nooks and crannies of the jewelry, leaving it sparkling clean.

-

Steaming and Final Inspection: A final steam clean ensures absolutely no residue remains. Then, the piece undergoes a rigorous final inspection under magnification. These final checks for rush orders are absolutely critical, ensuring every facet gleams, every prong is perfectly set, and there are no lingering imperfections. The final polish is where the piece truly comes alive. It's the last touch before it reaches our client, and it must be flawless, regardless of how quickly it needed to be done. Not even fingerprints are allowed to remain on the finished piece.

For a "rush" job, every one of these steps is performed with maximum efficiency without sacrificing quality. This often means having dedicated polishers on standby, working seamlessly with the setters, and prioritizing the piece through the workshop. It’s a testament to the coordinated effort and commitment to excellence that defines Motek Jewelry's ability to deliver under pressure.

Phase 5: The Hand-Off and The Finish Line: Delivering Your Urgent Masterpiece

Question/Problem Addressed: What are the final logistical steps involved in getting a "rush" jewelry order from the workshop to the client, ensuring security, presentation, and timely arrival?

The moment of truth arrives after the polishing is complete and the final inspection passed. The dazzling piece of jewelry, born from a "rush" request, is now ready for its anxious new owner. But the "rush" doesn't end until it's safely in your hands. This final phase involves careful packaging, secure logistics, and clear communication.

-

Impeccable Presentation: Even in a hurry, presentation is paramount. The freshly polished jewelry piece is carefully placed in a luxurious Motek Jewelry box, often nestled in velvet or silk. For special occasions like weddings or anniversaries, we ensure the packaging reflects the significance of the event - with polished and lacquered wood boxes with custom messaging available upon request. A personalized touch, such as a hand-written note from Bentzion is often included, emphasizing the unique journey of the piece. This attention to detail reinforces the "Quality First" ethos of Motek Jewelry.

-

Secure and Expedited Shipping: For local clients, same-day or next-day pickup or personal delivery by a Motek Jewelry representative might be an option, offering the ultimate in speed and security. For clients further out, high-value, fully insured, and expedited shipping services are arranged. This typically involves:

-

Specialized Couriers: We partner with reputable couriers renowned for handling valuable goods. These aren't standard postal services; they often provide dedicated handlers and real-time tracking with proof of delivery.

-

Discreet Packaging: While the inner presentation is luxurious, the outer packaging is often discreet to avoid drawing unwanted attention to the valuable contents.

-

Insurance: Every "rush" shipment is fully insured, providing peace of mind for both Motek Jewelry and the client.

-

Tracking and Communication: Clients receive detailed tracking information and regular updates on their package's journey. Our customer service team is on standby to address any questions or provide real-time assistance.

-

-

Final Communication and Client Satisfaction: As the package makes its way, Motek Jewelry maintains open lines of communication. A confirmation email or call informs the client of the dispatch and anticipated arrival time. Upon delivery, a follow-up ensures the piece was received safely and that the client is completely satisfied. We encourage clients to share their experience and often offer advice on jewelry care and maintenance to ensure the longevity of their new treasure.

-

Beyond the Sale – Building Trust: For Motek Jewelry, a "rush" job is more than just a transaction; it's an opportunity to build lasting trusting relationships and demonstrate our unwavering commitment to client satisfaction. The ability to deliver exceptional quality under extraordinary time constraints often turns first-time "rush" clients into lifelong patrons. It showcases the dedication of the entire Motek Jewelry team and vendor partners to turning even the most urgent dreams into sparkling realities.

Whether it's a pair of last-minute lab-grown diamond hoop earrings for a bride or a bespoke custom piece crafted against the clock, Motek Jewelry is equipped to navigate the complexities of "rush" orders. Our blend of expertise, network, meticulous craftsmanship, and unwavering dedication ensures that your urgent jewelry needs are not just met, but exceeded.

Ready to turn your urgent jewelry dream into a reality? Don't hesitate, even if time is short. Reach out to Motek Jewelry today and let us guide you through the seamless process of a "rush" job.

Contact Motek Jewelry: Phone: 845-213-6087 Email: contact@mymotek.com Website: mymotek.com (or shop directly on our site for stock pieces, or start a custom inquiry!)

Industry Expert References:

-

Gemological Institute of America (GIA):

-

Reference: GIA is the world's foremost authority in gemology, providing education, research, and gem grading services. Their articles offer in-depth information on diamonds (natural and lab-grown), gemstones, and jewelry craftsmanship.

-

-

The Rapaport Diamond Report (RapNet):

-

Reference: A leading source for diamond pricing and market information, crucial for understanding diamond availability and pricing trends, especially for quick sourcing.

-

Link: While direct article links might be paywalled, general information on Rapaport can be found at https://www.rapaport.com/

-

-

American Gem Society (AGS):

-

Reference: A professional organization dedicated to consumer protection and ethical business practices in the jewelry industry, providing insights into quality standards and professional networks.

-

-

Jewelers of America (JA):

-

Reference: The national trade association for the retail jewelry industry, offering resources and best practices for jewelers, including operational efficiency.

-

-

National Association of Goldsmiths (NAG - now National Association of Jewelers, NAJ):

-

Reference: A UK-based organization providing training and industry standards, emphasizing craftsmanship and ethical practice in jewelry making and repair.

-

Link: https://www.naj.co.uk/

-